Problem formulation and theory:

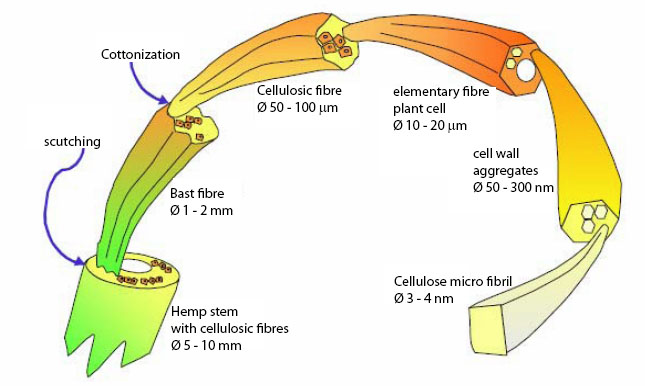

The goal of the project is to produce strong materials by use of plant fibres. These are mentioned as cellulosic fibres due to their high cellulose content The major challenge is to understand why the effective cellulose strength in cellulosic fibres is in the range of only 300-1500 MPa while the theoretical cellulose strength is 8000 MPa. To make composite materials for advanced purposes it is therefore required both to characterize and pretreat the cellulosic fibres. Characterization of the fibres and the resulting biocomposite with electron microscopy and X-ray diffraction can generate information about the defects and the nanostructure. This can allow establishment of specific enzymatic pretreatment needed for improvement of the cellulosic fibres. A model of the fibres is shown in the picture below.

Relevance of project:

Today, polymers and synthetic fibres such as glass fibres are generally produced with usage of fossil fuel, such as coal and oil. Sustainable materials are therefore needed due to depletion of oil reservoirs and natural resources. They include cellulosic fibre reinforced biocomposites, which can be produced using fibre mats that have 40% lower density than glass fibres. Biodegradable materials can then be made, which will improve the recycling of raw materials. A central point in the project is therefore to compare the industrial production pathway with hightech laboratory pathways in the fibre preparation.

Summary:

This project aims for a suitable way to isolate cellulosic fibres from hemp and flax plants so that these fibres can work as a strong reinforcement agent in biocomposite materials. The fibres will be isolated from the plants by optimized mechanical processes to reduce the fibre damage. Enzymatic treatment of the bast fibres from the plants will be established as a specific process to isolate the cellulosic fibres with less fibre damage than the process of chemical hydrolysis of the pectin and hemicellulose content. The microbial community involved in the retting process will be characterised. The mechanical damage, nanostructure and crystallinity of the cellulosic fibres will be characterized by electron microscopy and X-ray diffraction. The cellulosic fibres will be aligned in selected biopolymers aiming at biocomposite materials with high stiffness and strong interface bonding. Finally the biocomposite durability will be determined in fungal decay studies.